Long Shank Type Crossarm Pins

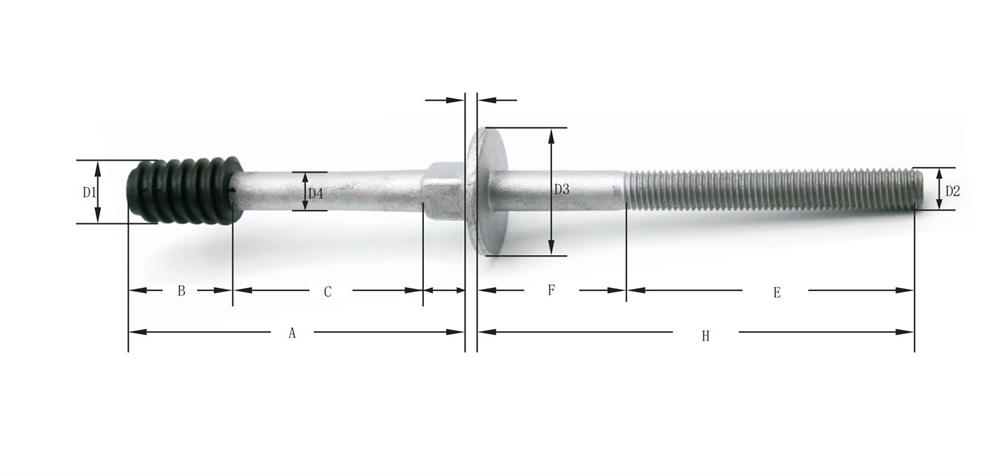

Name:Long Shark Type For Crossarm Pins

Material:Material:carbon steel with nylon alloy top

Finish:Hot Dip Galvanized Per ASTM A153 Class 3

Type:Insulator Pin

Application:Pole Line Hardware Or Other Fastener

Packaging: Carton Box And Pallet

OEM:Accepted

Description

| Parts No. | Description | Material | Bolt Dia | Length |

| CW-LCP | Long Shank Nylon Crossarm Pins | Steel Galvanized+Nylon | 5/8″,3/4” | 5″ X 6-1/2″, 5″ X 5-3/4″, 6″ X 5-3/4″, 6″ X 6-1/2″ |

Crossarm pins are components of crossarms in transmission line systems. The cross arm pin joins cross arms together. The cross-arm pin base is fitted in a cross-arm hole of one cross arm and the crossarm pinhead is placed on top of the cross-arm pin body to hold it into position so that they cannot move outwards.

Crossarm Pins are forged in one piece from carbon steel with large bases to distribute loads without crushing flat wood crossarms. A square wrenching shoulder is provided above the base for rotating the insulator groove into position.

Long shank pins come complete with a square washer, square nut and concave MF locknut. Short shank pins for steel crossarms are furnished with a square nut and split coil lockwasher.

Crossarm pins are used to mount spindle threaded insulators directly on crossarms.

Crossarm pins are forged from one piece hearth steel.

Broad base diameter distributes load without damaging crossarms.

Crossarm pins and components are hot dip galvanized to meet ASTM Specification A153.

Advantages of crossarm pins

1> They enable building a transmission line system that can resist winds up to 110 mph.

2> In cross arms of towers with crossarm pins, the weight is distributed equally so they are sturdy and capable of withstanding high winds.

3> They offer crossarms more strength to hold up the electrical transmission line wires that cross them. The crossarm pins are thick as compared to crossarm insulators, which means more strength.

4> The crossarm pins are easy to replace if they are broken or if they need maintenance. They typically last 25-50 years, and then they are replaced with a new cross arm pin.

5> Their bases may be bolted on to crossarms by means of nuts, bolts and washers that prevent them from falling off crossarms.