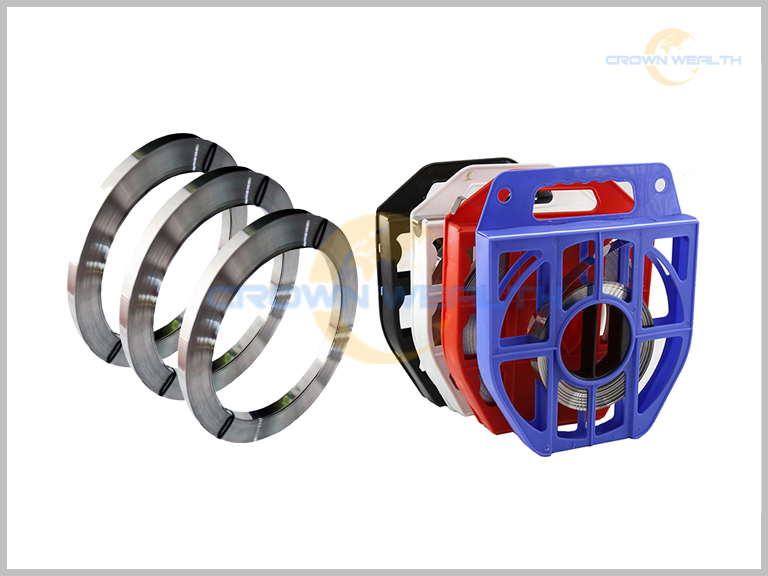

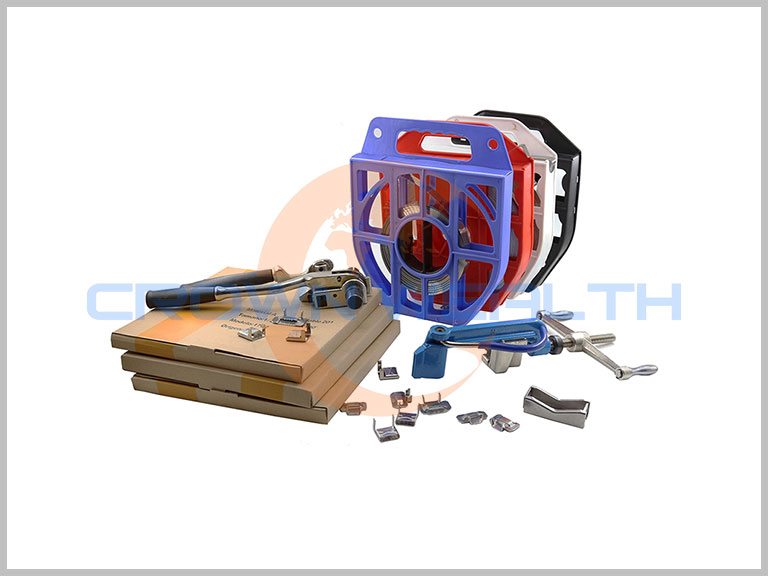

Stainless steel banding strap is a kind of metal steel straps, which is processed from stainless steel material. Commonly available are 201 and 304 stainless steel, both of which have excellent corrosion and rust resistance. Is there any difference between 201 stianless steel straps and 304 stainless steel straps? It takes an analysis of their raw materials to figure out fundamentally.

The difference between 201 and 304

- Commonly used stainless steel sheet is divided into two steel grades 201 and 304, in fact, the composition of these two steel grades is different. 304 quality is better, but the price is more expensive, 201 quality is worse.

- The composition of 201 is 17Cr-4.5Ni-6Mn-N, which is a substitute for nickel-saving steel and 301 steel. After cold working, it has magnetic properties and is used for railroad vehicles.

- 304 has a composition of 18Cr-9Ni and is the most widely used stainless steel and heat-resistant steel. It is used for food production equipment, chemical equipment, nuclear energy, etc.

- 201 contains high manganese, the surface is very bright, dark and bright, high manganese content is easy to rust. 304 contains more chromium, the surface is matte, no rust. The two are put together for comparison. The most important thing is that the corrosion resistance is different. Because 201 contains low nickel, the price is lower than 304, so the corrosion resistance is not as good as 304.

When it comes to fatigue resistance, 201 has higher hardness and less toughness than 304, but 304 has better fatigue resistance.