Plastic coated stainless steel cable ties and extruded stainless steel cable ties are actually the same thing, just called different

The disadvantages of this type of cable tie:

1,are made of plastic coating (PVC coating), no flame retardant effect, black smoke in case of fire, not environmentally friendly, not fireproof. 2,PVC coating if exposed to normal temperature or direct sunlight, the life is very short, directly dry the skin. 3,The unit price will be 1.5-2 times higher than the light belt (without any coating).

Spraying plastic is currently the process of spraying black paint in Zhejiang. This cost is much lower than that of plastic coated (in the extrusion process), but it is easy to fall off during use. It is better to use a light belt (no coating), and a good manufacturer’s belt will have the process of cutting the edge.

The use of overmolded cable ties or plastic ties is basically a consideration for protecting cables or conducting electricity. In fact, it is only necessary to use a light strip with a trimmed corner to protect the cable. The rounded corners will not cut the product. The problem of electrical conduction is not solved by the plastic cable ties. If it is really demanding, choose a stainless steel cable ties. This is the safest product certified by the European Union.

Anti-plastic is to spray the plastic powder evenly by heating the metal.

Forming a layer of plastic film on the genus , or heating

The plastic liquid is put into the metal parts to cool it, and then the plastic material is coated on the gold.

It belongs to the surface. This kind of process has no need for molds and processing costs.

Low, easy to shape, workable, various shapes, etc.

General use. But the products of the fence net are all powdered.

According to whether it is necessary to add heat to hot plastic and cold plastic, press

According to the anti-plastic raw material, it can be divided into liquid plastic and powder plastic.

Stainless steel cable tie selection method:

1 First, confirm the condition of your own tying object, whether it is a corrosive environment, or an ordinary natural environment, and choose a certain material.

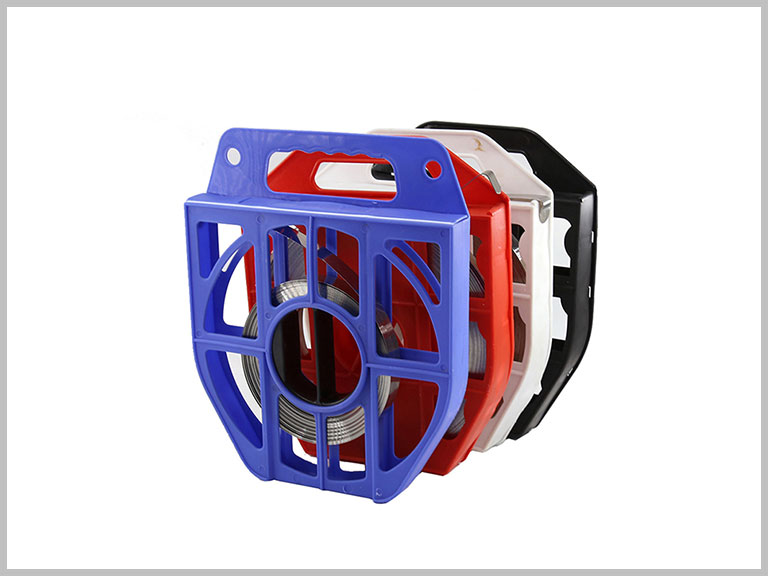

2 Confirm the requirements of the object you are tying, whether it is very tight, or just a normal tightening, hard, hard or soft, and determine the different styles of the cable, such as a roll of stainless steel cable ties, plastic coated Stainless steel cable ties, stainless steel cable ties, beaded, coated and more.

3 Determine the brand first of all to meet their own requirements to choose the best price-performance brand, not the more expensive the better, not the cheaper the better, the quality may be guaranteed, but there are more possibilities. The cheaper it is, the better it is. Some of the raw materials for the straps are much cheaper than the products. It is obvious that the manufacturers are likely to cut corners.

How to use stainless steel cable ties

- Place the stainless steel cable tie in the open slot of the knife edge and the rotating shaft.

- Move the gear handle back and forth to tighten the stainless steel belt.

- Push the handle forward, pull down the handle, cut off the strap, lock the buckle, and remove the tool.