Stainless steel strapping has a wide range of uses in many industries, however, in all cases, its overall performance is top notch. Stainless steel strapping (alt name metal banding strap, stainless steel banding, stainless steel banding straps, steel strapping straps, steel banding straps ) is designed to be strong and durable, so when materials need to be secured in place, stainless steel strapping may be the best choice.

- The first choice is usually the type with standard or safety edges. Whenever they are a danger to stainless steel straps that come into contact with bare hands then the safety edge is important. This is used for signs, trash bins, business Christmas decorations, cables, standard edge banding is widely used in the HVAC industry and for oil and gasoline insulated fixed pipe metal sheathing.

- The second option is stainless steel buckle, stainless steel buckle is the most popular in the sign industry, because the sign industry is usually smaller in diameter of the column, the use of stainless steel buckle and teeth.

Direct Factory Supply Stainless Steel Strapping

To secure the stainless steel strapping, it is first cut to the desired circumference (usually allowing for greater contact), then passed through the buckle and folded over itself again.

Stainless steel straps are wrapped around the object to be secured this can be a road sign, a tank, or even a Christmas decoration …… The other side of the stainless steel straps is also passed through the buckle. Use a strapping tool to increase the tension until it is firmly secured. Then cut the stainless steel strapping leaving a short piece long enough to return through the stainless steel buckle. Now that you may know what stainless steel strapping is, let’s move on to that feature.

Features of stainless steel straps?

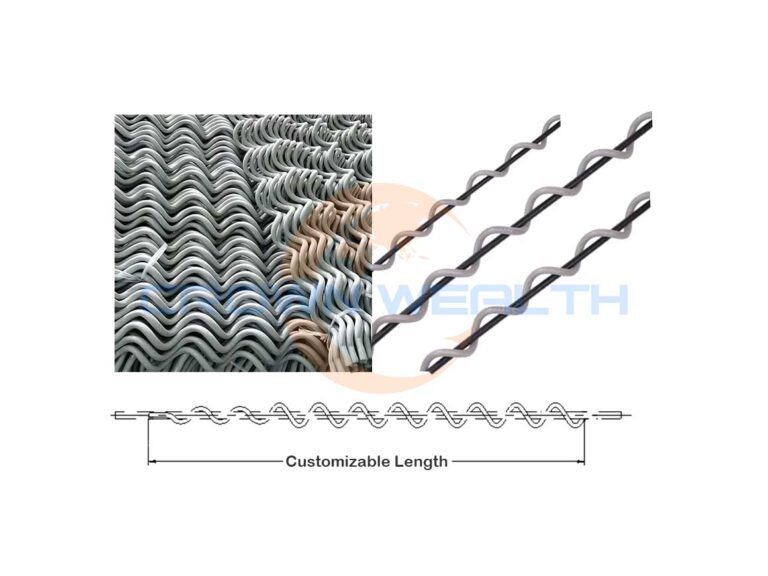

- Self-made, users can customize any length as needed.

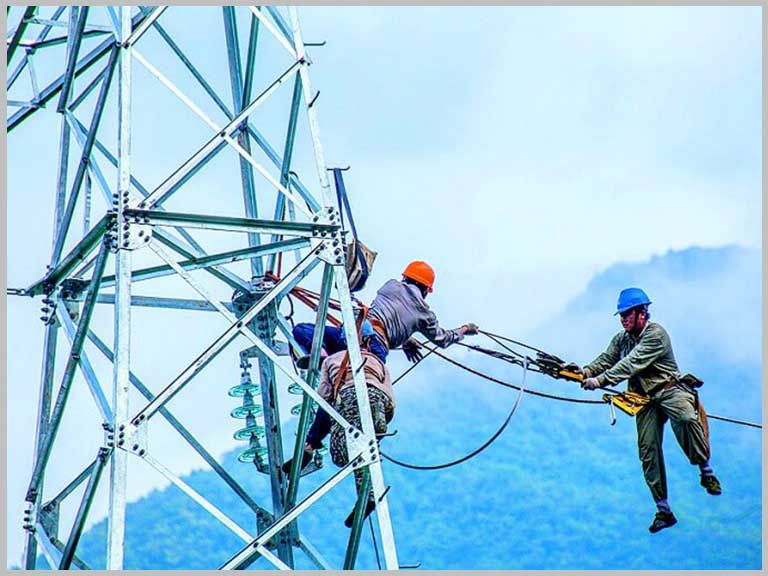

- Used for bundling cables, billboards, traffic signs, pipes, etc.

- Choose different sizes according to different use environments.

- You can use stainless steel strapping tool to install stainless steel strapping.

- Can be used with L-shaped stainless steel buckle, tooth-shaped stainless steel buckle, stainless steel flat buckle, screw-type stainless steel buckle.

- Stainless steel ties, buckles use high-quality materials stainless steel 201 304 316, with its strong bonding strength is widely used in a variety of fields.

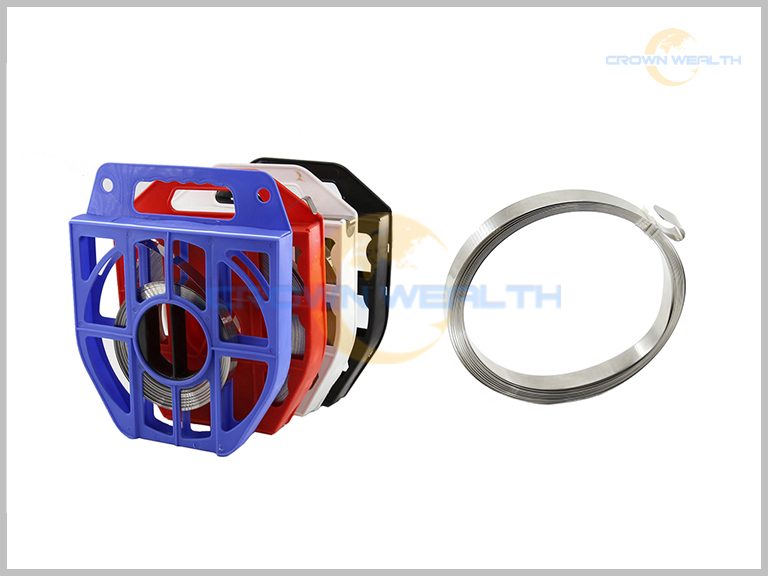

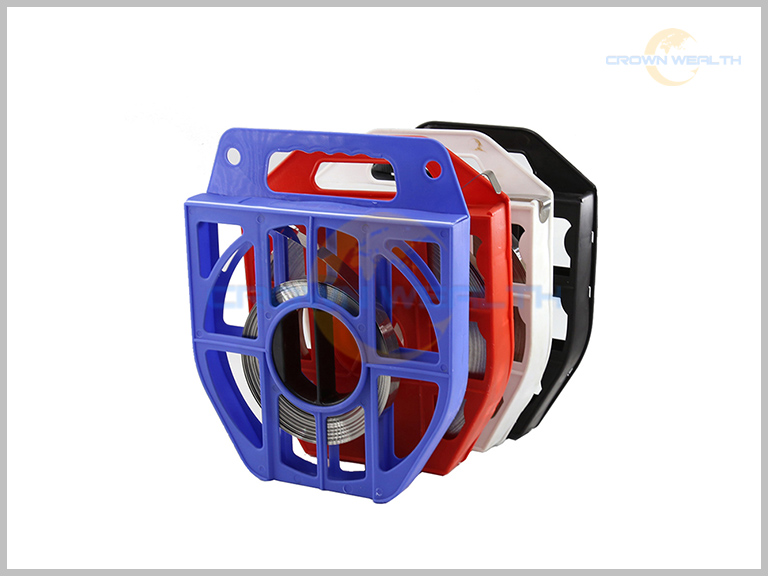

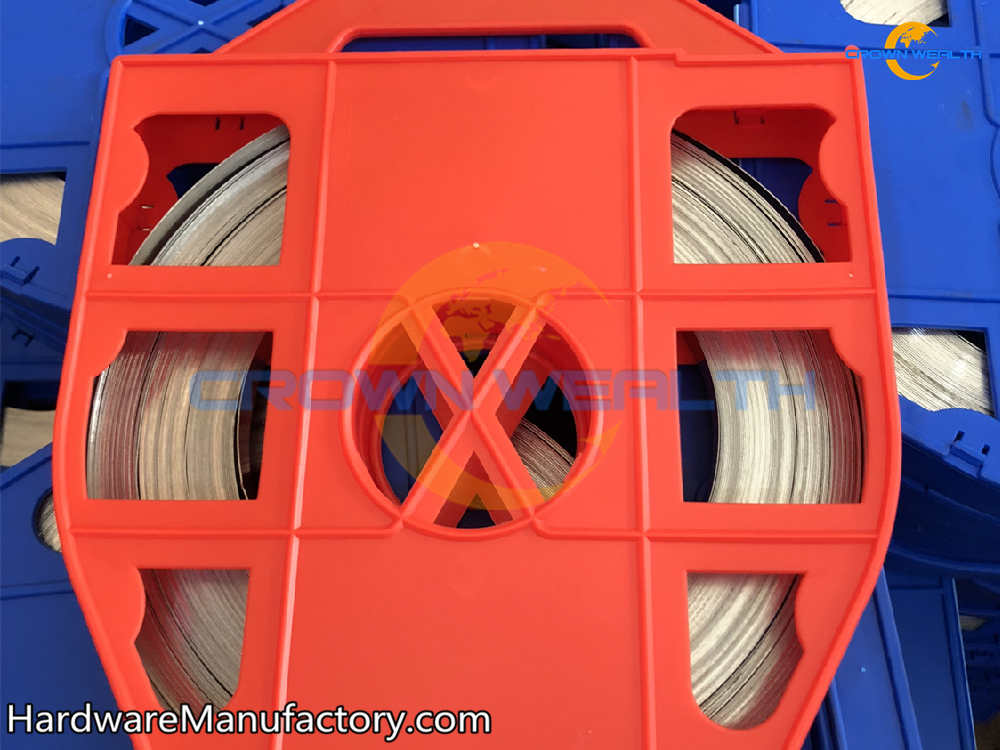

- Sturdy and practical carton packaging, existing simple plastic waterproof packaging, new portable box, convenient handle, transparent design can show the remaining stainless steel strapping, pull out as needed when using.

- Stainless steel strapping, smooth R rounded edges, bright surface, good resistance to oxidation and corrosion, is the industry standard for general strapping solutions.

- It is safe and easy to install, it can also be double strapped to increase load capacity. It is more suitable for harsh environments such as corrosion, humidity and seawater.

- It can be processed to any size.

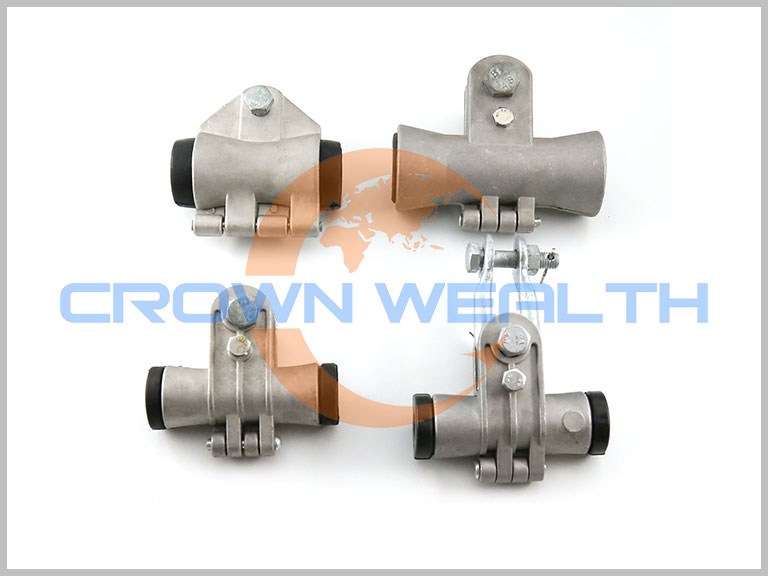

Strapping tool

Stainless steel strapping tool is suitable for stainless steel band strapping, with the function of tensioning and cutting stainless steel band strapping, easy to operate, convenient and practical, it is the most commonly used stainless steel strapping tool.

The strapping tool is suitable for stainless steel strapping with width 6.5-20mm and thickness not exceeding 0.8mm.