201 stainless steel has the characteristics of polishing, no bubbles, no pinholes, etc. . 201 stainless steel plate has the ability to resist general corrosion similar to the unstable nickel-chromium alloy 304. Long-term heating of 201 stainless steel plate in the temperature range of chromium carbide may affect the alloy 321 stainless steel plate and 347 in harsh corrosive media. 201 stainless steel plate is mainly used for high temperature applications. High temperature applications require the material to have strong sensitization resistance to prevent intergranular corrosion at lower temperatures.

304 stainless steel is a common material in stainless steel, with a density of 7.93 g/cm3, which is also called 18/8 stainless steel in the industry. High temperature resistance of 800 degrees, with good processing performance and high toughness, it is widely used in industry and furniture decoration industry and food and medical industry. Common labeling methods on the market include 06Cr19Ni10 and SUS304. 00Cr19Ni10 generally means national standard production, generally means ASTM standard production, and SUS 304 means Japanese standard production. 304 is a versatile stainless steel, which is widely used to make equipment and parts that require good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 18% chromium and more than 8% nickel. 304 stainless steel is a grade of stainless steel produced in accordance with the American ASTM standard.

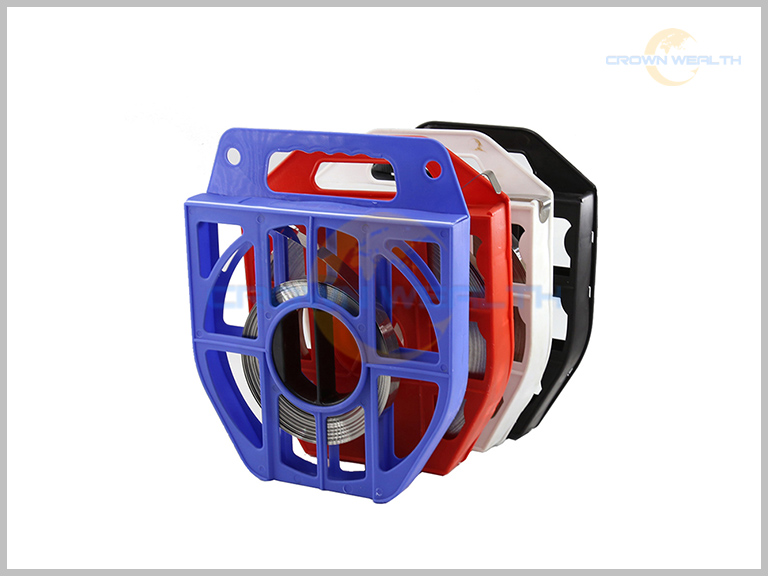

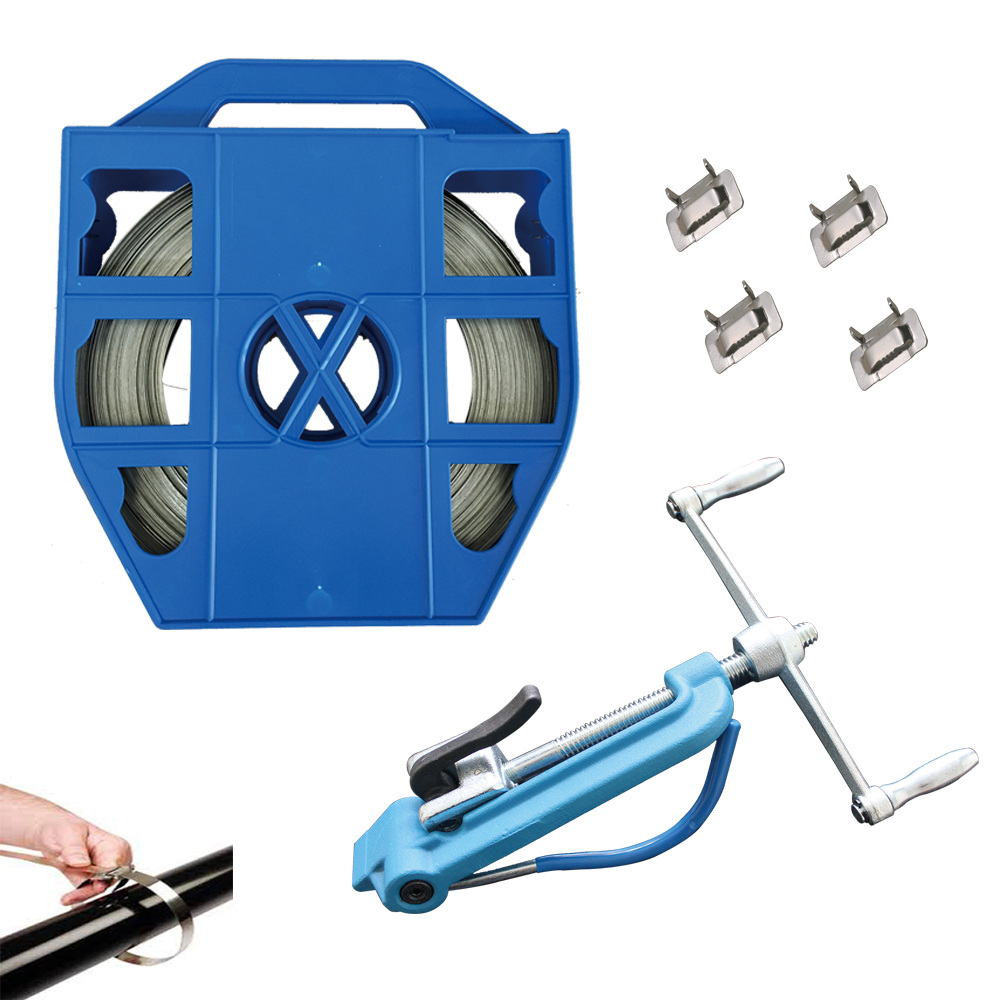

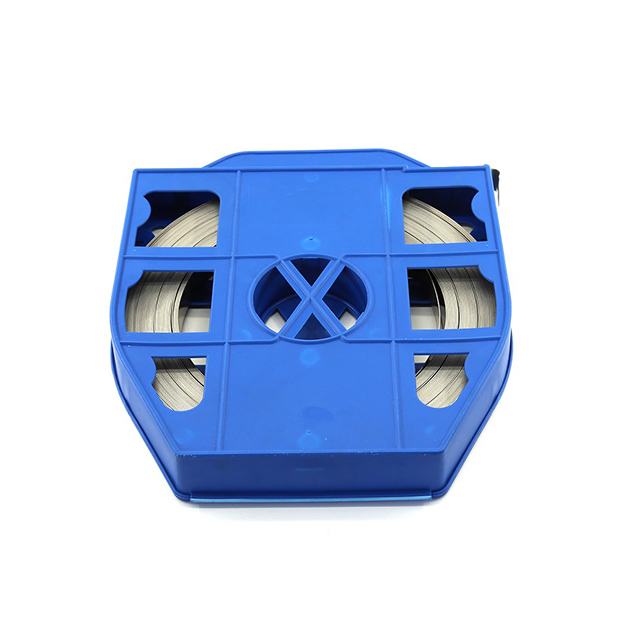

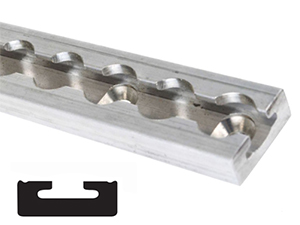

SS bandding strap, seales & tool

banding tool

stainless steel banding strap, clamp

package of SS straps

price

201 and 304 stainless steel plates, the most intuitive parameter for ordinary people, is its price. The quality of 304 stainless steel plate will be better, so its price is also more expensive. If the price is lower, it should be 201 plate.

use

201: Mainly used in industries such as railways and heavy vehicles.

304: Food processing equipment, industrial production equipment, etc.

Element

201: (C) Carbon: ≤0.15, (Ni) Nickel: 3.5-5.5, (Si) Silicon: ≤1.00, (Mn) Manganese: 5.5~7.50, (Cr) Chromium: 16.0~18.0, (N) Nitrogen: ≤0.25, (P) Phosphorus: ≤0.060, (S) Sulfur: ≤0.030

304: C: ≤0.08, Mn: ≤2.00, Ni: 8.0-11.0, P: ≤0.045, S: ≤0.030, Si: ≤1.00, Cr: 18.0-20.0

Corrosion resistance

201: The material has a relatively high manganese content and is easy to rust.

304: The chromium content of the material is relatively high, and it is not easy to rust.

performance

201: The hardness is relatively high, and it is more used in industry.

304: The hardness is softer, and the corrosion resistance is better.