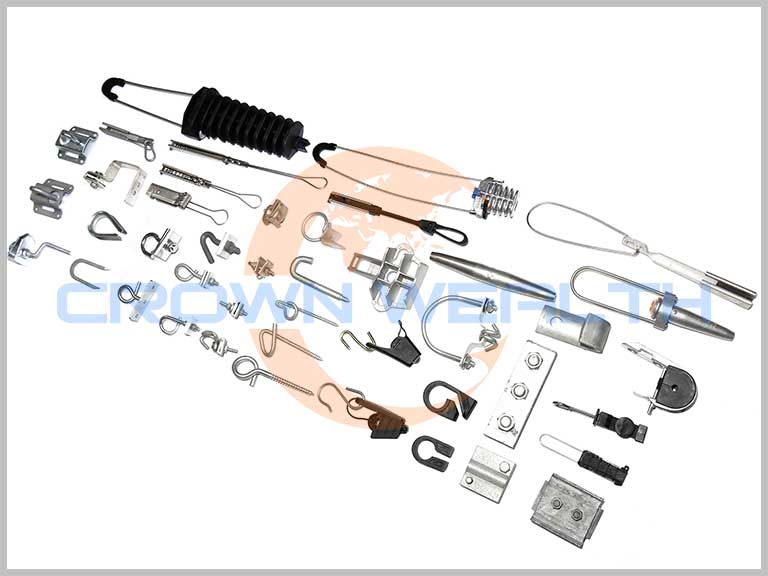

The drop wire clamp is composed of a body, a wedge, and a shim. A solid wire bail is crimped to the wedge. All parts are made out of stainless steel. Fiber optic drop cable clamp made of stainless steel material. It is furnished with a perforated gasket which increases the tension load on the drop clamp without cable slip and damage, supplying a long time usage life. The stainless steel wire can be used with drive hooks, pole brackets, FTTH brackets, and other fiber optic cable fittings or hardware.

A drop wire clamp enables a cable, like a coaxial cable, to get attached and supported to a pole, building, or any other kind of support wire in a way that decreases any compromise made to the signal transmission capacity of the drop wire cable. The clamp is also beneficial as it supports the cable weight and sets the tension on the line as it relieves the stress on the points of attachments, such as the juncture through a building or a pole.

A drop wire clamp is utilized to augment a single and two paired fiber drop wire at drive hooks, span clamps, house hooks, and various other attachments for the drop. In addition, drop wire clamps are utilized to support the aerial service terminals’ drop span at the messenger and building strand. In most cases, these clamps are removable.

Installation:

1. Place the cable in the stainless steel drop wire clamps‘ body.

2. Place the shim in the fiber optic drop cable clamp body over the cable, the grip side in contact with the cable.

3. Insert the wedge through the front of the body and pull to secure the cable.